color masterbatch

plastic is a versatile material used in a variety of forms and hues. a very interesting fact about plastic is the colorless nature of certain grades of this substance. indeed, other materials and additives give plastic its diverse colors and enhance its properties.

these materials are known as masterbatches and come in a variety of forms. masterbatches significantly impact the plastics industry, particularly color masterbatch, which add different colors to plastic. these questions arise: what is a masterbatch, and how does it work?

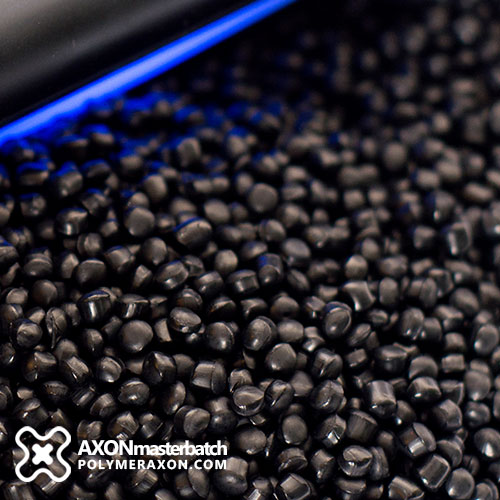

masterbatches are high-temperature mixtures of base plastic materials and colorants. once cooled, the materials can be cut and shaped. these materials are solid and available in fine granules or cut pieces.

notably, these materials must be used in a specific amount during plastic production for the final product to have the desired color or properties.

what is a color masterbatch?

as the name suggests, this material is used to color plastics and is available in over 200 colors.

masterbatches are considered raw materials. they primarily comprise base materials like polyethylene, polypropylene, polystyrene, abs, polycarbonate, polyamide, and similar substances. different colors can be used depending on the situation and the materials available.

in short, the raw materials are combined with a tiny percentage of a mixture (powder) known as pigment to produce a masterbatch.

this masterbatch’s 0.5-3% consumption rate is sufficient to color the desired raw materials. indeed, a small amount of masterbatch can impart color to a vast object, just as a single drop of ink can tint an entire bucket of water.

as a result, the final plastic product can be made in any color. these materials have a significant impact on the plastics industry. the color this material imparts to products is responsible for most of their beauty.

at axon polymer, our sales experts are committed to helping you choose the most appropriate product for your requirements. we offer thorough guidance to help you make a well-informed purchase decision.

applications of color masterbatch

the primary application of masterbatches is to add color to plastic materials. polymer materials are inherently colorless, which limits their standalone use; therefore, they require the addition of masterbatches (ranging from 1 to 3 percent). it is important to note that masterbatches can introduce specific features to polymer materials beyond color.

the plastics industry makes extensive use of these materials today. although there are various methods to color plastic, the masterbatch remains the preferred option for manufacturers due to its numerous advantages, as detailed below:

- plastic product manufacturers are using fewer synthetic polymers and increasingly incorporating more natural polymers, which are more cost-effective. the key point is that incorporating a color masterbatch can enhance the compositions, allowing for the use of cost-effective natural polymers. the calcium carbonate masterbatch is a particularly effective way to improve natural polymer compounds.

- achieving the ideal color is simple. these materials allow the plastic to acquire the exact color desired. using these materials proves to be more cost-effective than alternative methods.

- incorporating these materials facilitates the production process.

- compared to other pigments and powders, this material is cleaner and leads to an ideal result.

- working with these materials does not generate dust and poses no risk to human health. other substances pose specific threats to individuals and the environment.

- the most significant advantage is the ability to color plastic products. this material’s wide range of variations facilitates a more effective and comprehensive use of products.

types of color masterbatches

given the widespread use of these materials, various types are available. below, we examine the most common ones.

- yellow masterbatch

- white masterbatch

- black masterbatch

- gold and silver masterbatch

- green masterbatch

- blue masterbatch

- red masterbatch

this section focuses exclusively on color masterbatches; separate sections describe other types in greater detail.

factors affecting the price of color masterbatches

masterbatch price: the price is determined by various factors, depending on the type of the masterbatch. below, we will look at the key factors that influence the cost of each type of masterbatch.

masterbatch’s daily price

the daily price of a masterbatch appears below. it typically changes in response to fluctuations in the cost of polymer materials. we will provide this price on a daily basis.

color masterbatch price from USD 2.13 to USD 9.14 per KG

color masterbatch price

the final price of the color masterbatch is determined by the percentage of pigment used, its type, and the pigment manufacturer’s country of origin. it is worth noting that the higher the percentage of pigment used, the stronger the color. subsequently, a lower rate of material can be used to achieve the desired color. however, because this material is a powder that mixes with other materials, it has some limitations. it is not readily possible to add 50 or 100 percent pigment.

the type of color is also an essential factor in determining price, as different colors have different prices. for example, dark and light red have different prime costs and prices.

pigments are typically produced in four countries: canada, germany, india, and china. these pigments are among the best in the world and, as a result, have higher quality and cost.

tips for buying colour masterbatch and selecting color masterbatch manufacturer

given the high demand for masterbatches, plastics, and their derivatives, it is critical to identify the best masterbatch manufacturer and supplier. using high-quality materials for color and other additives results in superior products. this, in turn, increases consumer satisfaction and demand for specific products.

polymer engineers in companies must conduct extensive research and investigation to produce high-quality masterbatches. in addition to expert quality control, these businesses must hold quality certifications. finally, consumers—aware of societal demands and seeking to improve the quality of their products—require such materials to complete their formulations and manufacture their products.

given the wide range of colorants and additives at our disposal, incorporating them into the manufacturing process provides a viable opportunity to improve the efficiency of products. the resulting advantages hold considerable value for both manufacturers and consumers alike.